Human-centered Hankook Fire Fighting Equipment Co.,Ltd

We will be your safety guard company so that everyone can enjoy safe and convenient life.

Components and Specifications

- HK-6500

- HK-5000/5100

- Detail information

Components and Specifications

Components and Specifications

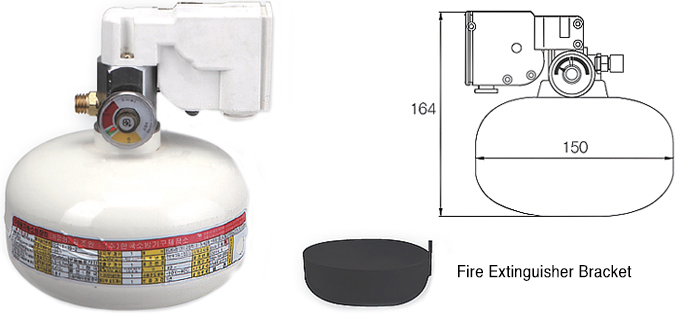

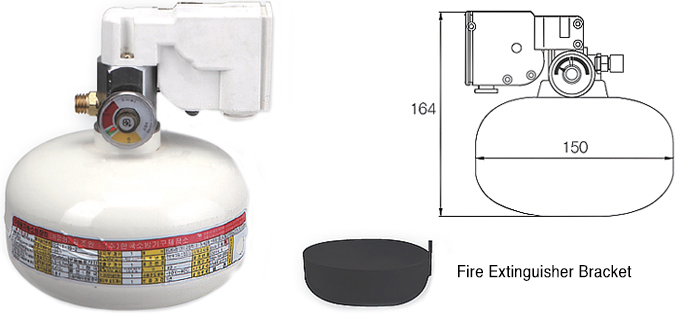

Fire Extinguisher HKF-310

| How to operate | Fire extinguishing chemical is ejected along with ejection tube, with the pressing pin pressed by operation of the cap linked to a motor |

|---|---|

| Fire Extinguishing Container | Fire Extinguishing Container KSD 3698 / Thickness 1.2t / Inside Volume 1025ml / Chemical Quantity 0.8ℓ |

| For pressurization | Working Pressure 0.75 ~ 0.98㎫ |

| Gas Container | Instruction Pressure Gauge Pressure Sensing Method Expansion and Contraction Type |

| Dimension(㎜) | 150 (W) × 164(H) |

| Weight(g) | 1900 |

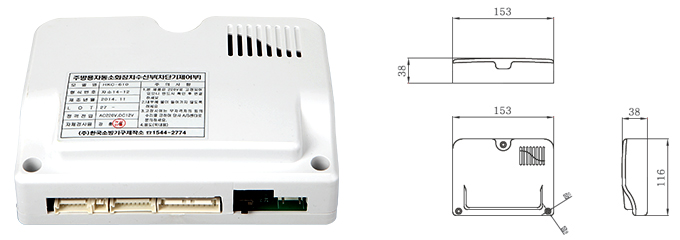

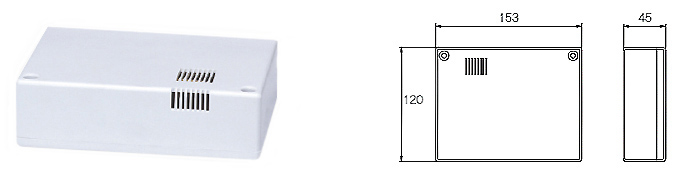

Reception Part HKC-650 / HKC-650T

| Rated Voltage | AC220V / 60㎐ |

|---|---|

| Power Consumption | 140W |

| Back-up power | Ni-Cd Battery, DC 12V 600mAh |

| Operating Temperature Range | -10 ~ 40℃ |

| Communication Module | RS-485 내장(Option) |

| Dimension(㎜) | 153(W) × 116(H) × 38(D) |

| Weight(g) | 700 |

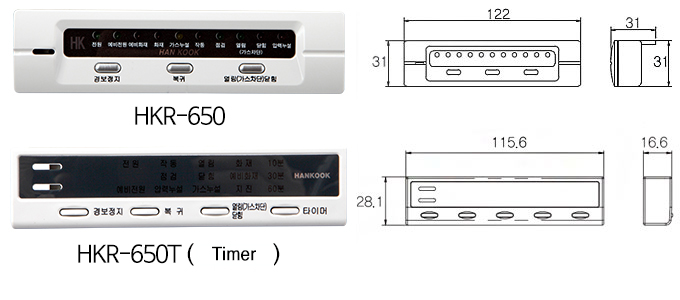

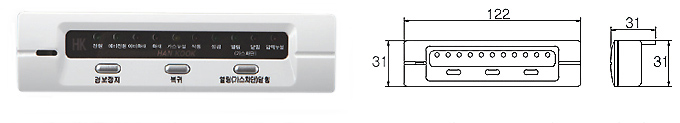

Control HKR-650 / HKR-650T (timer)

| Rated Voltage | DC 12V |

|---|---|

| Functions | Remote Control and Indication of Functions |

| Operating Temperature Range | -10 ~ 40℃ |

| Dimension(㎜) | HKR-650 : 122(W)×31(H)×29(D) HKR-400 : 115.6(W)×28.1(H)×16.6(D) |

| Weight(g) | 39 |

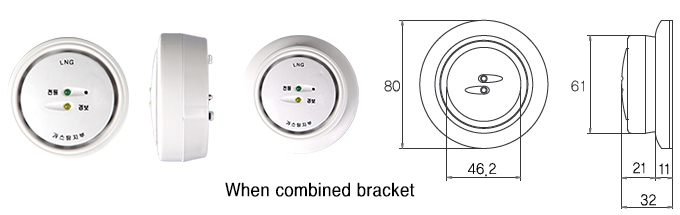

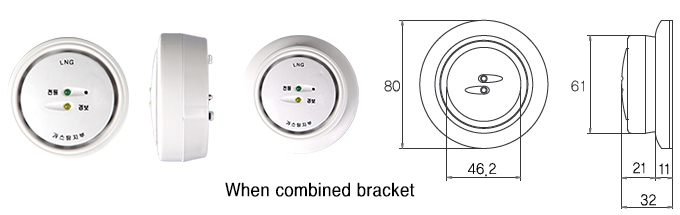

Gas Detection Part HKD-410

| Rated Voltage | DC 12V |

|---|---|

| Functions | Remote Control and Indication of Functions |

| Applicable Gases | LNG, LPG |

| Alarming Density | LPG 600 ~ 4,500ppm / LNG 600 ~ 12,500ppm |

| Gas Detection Method | Diffusion Type |

| Gas Detection Element | Catalytic Combusion Method(Instant Type) |

| Dimension(㎜) | 61 Ø × 32(D) |

| Weight(g) | 60 |

※ Caution - When the gas detection part is inspected, the gas for test purpose should be used.

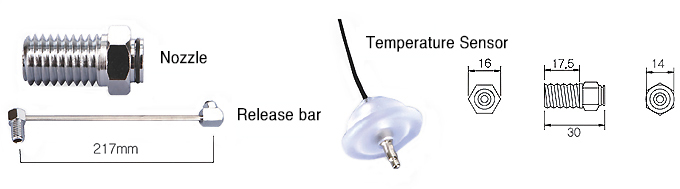

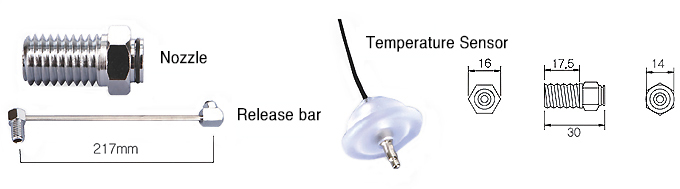

Nozzle & Temperature Sensing Part HKT-300 / HKN-200

| Primary Sensing Part | kind : Temperature Sensing Type(Thermistor Type) Nominal Working Temperature : 95℃ |

|---|---|

| Secondary Sensing Part | kind : Temperature Sensing Type(Thermistor Type) Nominal Working Temperature : 135℃ |

| Spray Nozzle | Discharging Time : 12 seconds Discharging Angle : 80˚ Nominal Protection Space : 695㎜ × 695㎜ Effective Installation Height : 500 ~ 700㎜ |

Gas Shut-off Device HKS-220 / HKS-615N / HKS-620 / HKS-610

Components and Specifications

Components and Specifications

Fire Extinguisher HKF-310

| How to operate | Fire extinguishing chemical is ejected along with ejection tube, with the pressing pin pressed by operation of the cap linked to a motor |

|---|---|

| Fire Extinguishing Container | Fire Extinguishing Container KSD 3698 / Thickness 1.2t / Inside Volume 1025ml / Chemical Quantity 0.8ℓ |

| For pressurization | Working Pressure 0.75 ~ 0.98㎫ |

| Gas Container | Instruction Pressure Gauge Pressure Sensing Method Expansion and Contraction Type |

| Dimension(㎜) | 150 (W) × 164(H) |

| Weight(g) | 1900 |

Reception Part HKC-500/510

| Rated Voltage | AC220V / 60㎐ |

|---|---|

| Power Consumption | 140W |

| Back-up power | Ni-Cd Battery, DC 12V 600mAh |

| Operating Temperature Range | -10 ~ 40℃ |

| Communication Module | RS-485 is in-built(Option) |

| Dimension(㎜) | 153(W) × 120(H) × 45(D) |

| Weight(g) | 700 |

Control Part HKR-300

| Rated Voltage | DC 12V |

|---|---|

| Functions | Remote Control and Indication of Functions |

| Operating Temperature Range | -10 ~ 40℃ |

| Dimension(㎜) | 122(W)×31(H)×29(D) |

| Weight(g) | 39 |

Gas Detection Part HKD-400

| Rated Voltage | DC 12V |

|---|---|

| Applicable Gases | LNG, LPG |

| Alarming Density | LPG 600 ~ 4,500ppm / LNG 600 ~ 12,500ppm |

| Gas Detection Method | Diffusion Type |

| Gas Detection Element | Catalytic Combusion Method(Instant Type) |

| Dimension(㎜) | 61 Ø × 32(D) |

| Weight(g) | 60 |

※ Caution - When the gas detection part is inspected, the gas for test purpose should be used.

Nozzle & Temperature Sensing Part HKT-300 / HKN-200

| Primary Sensing Part | kind : Temperature Sensing Type(Thermistor Type) Nominal Working Temperature : 95℃ |

|---|---|

| Secondary Sensing Part | kind : Temperature Sensing Type(Thermistor Type) Nominal Working Temperature : 135℃ |

| Spray Nozzle | Discharging Time : 12 seconds Discharging Angle : 80˚ Nominal Protection Space : 695㎜ × 695㎜ Effective Installation Height : 500 ~ 700㎜ |

Gas Shut-off Device HKS-600 / HKS-220 / HKS-800

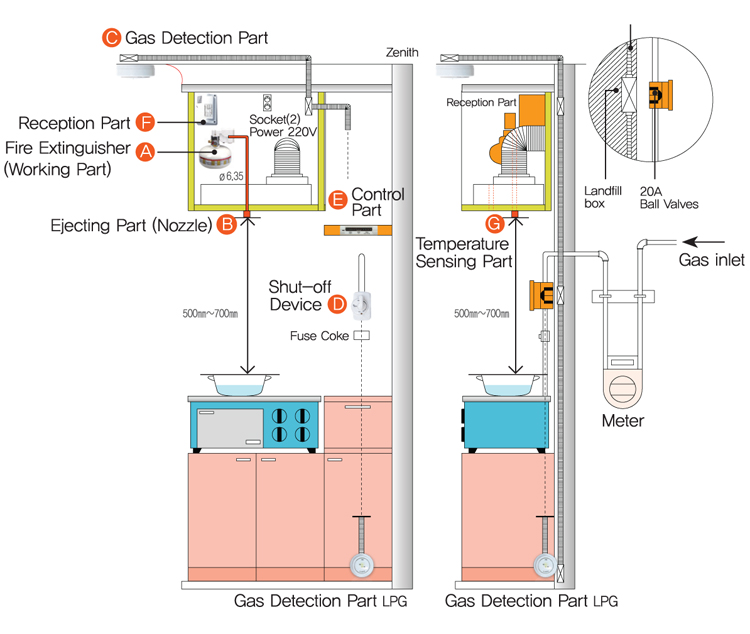

Installation drawing and mounting drawing of the automatic fire extinguishing apparatus for kitchen in the residence

Installation drawing and mounting drawing of the automatic fire extinguishing apparatus for kitchen in the residence

A - Fire Extinguisher (Working Part) / B - Ejecting Part (Nozzle) / C - Gas Detection Part

D - Shut-off Device / E - Control Part / F - Reception Part / G - Temperature Sensing Part

| Installation Position of Gas Detection Part | Considerations in piping/wiring | Installation Position of Nozzle/Temperature Sensing Part |

|---|---|---|

| - For LNG : within 30cm from ceiling - For LPG : within 30cm from floor - Install the product at the place not nearer than 1m diameter and not farther than 4m diameter from a gas apparatus (gas stove) |

- Gas Detection Wire Embedded Pipe PVC duct ø16 Max. Length 3m Electric wire UTP 4P or more - Gas Shut-off Wire Embedded Pipe PVC duct ø16 Max. Length 5m Electric wire UTP 4P or more - When embedding PVC duct, use dual-outlet socket box. · Please consult with our company if the installation of longer than maximum length is needed. · Shut-off device should be installed within 2m from kitchen piping opening and closing valve, in such a way that constant checking can be available. |

· Install them in accordance with effective installation height and protection space defined in the type approval · The height of nozzle is 500~700mm |

※ Nominal protection space and effective installation height may vary depending on the types.

Fire extinguishing test process of the automatic fire extinguishing apparatus for kitchen in the residence

Fire extinguishing test process of the automatic fire extinguishing apparatus for kitchen in the residence