Kfire is with you to Keep your Safety and Happiness

Uni Home

Uni Home

| Installable without a hood | Can be installed in kitchens or auxiliary kitchens without upper cabinets or a hood |

|---|---|

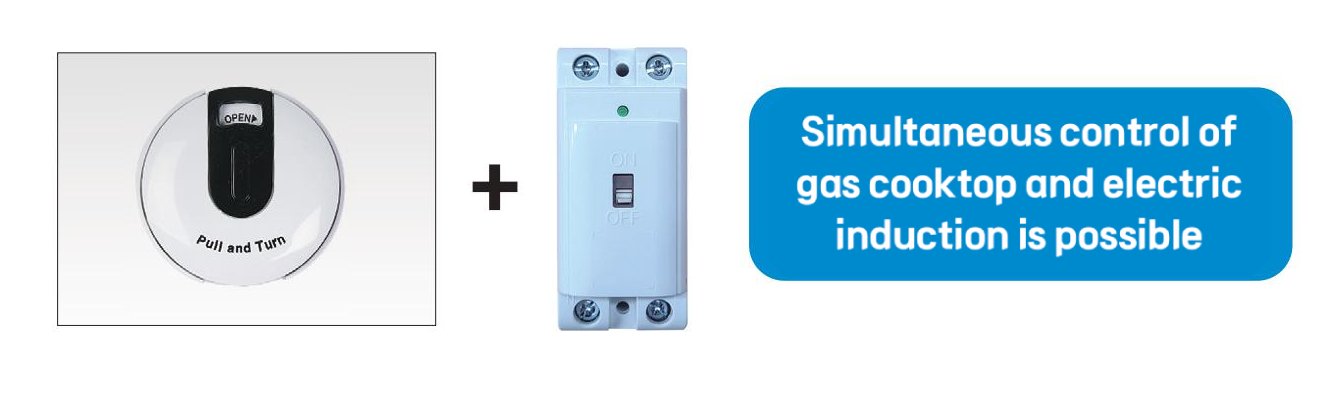

| Wireless control function | Wired/wireless electric shut-off allows for induction control |

| System interlocking | Can be linked with the automatic fire extinguishing system for air conditioners |

| Air conditioner shut-off interlocking | Can wirelessly shut off the air conditioner power |

| Extinguishing agent selection | Can use various extinguishing agents such as enhanced liquid or CO₂ |

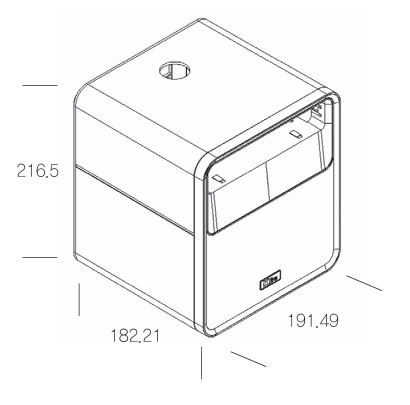

| Dimensions (W×D×H) | 191.49 mm × 182.21 mm × 216.50 mm |

|---|---|

| Spray Pressure | 1.8 Mpa |

| Operating Temperature Range | -10℃ ~ 40℃ |

| 1st Sensor Activation Temperature | 95℃ |

| 2nd Sensor Activation Temperature | 135℃ |

| Spray Nozzle Discharge Time | 12seconds |

| Spray Nozzle Discharge Angle | 80° |

| Power Supply | DC 12V or AC 220V |

| Battery Capacity | 300 mAh |

| Extinguishing Agent | Enhanced Liquid |

Components and Specifications

Components and Specifications

자소 23-22-1, 23-22-2, 23-25, 24-6, 24-5, 23-11-1, 24-8, 24-9, 23-28, 24-38, 24-40, 24-33

| Dimension(㎜) | 150 (W) × 164(H) |

| Capacity(ℓ) | 0.8 |

| Weight(g) | 1900 |

| Charging Gas | N2 |

| Main Ingredient | Potassium Acetate(CH3COOK) |

| Rated voltage | DC 12V |

| Dimension(㎜) | KAR-CP-FO-22-1 : 129(W) X 30(H) X 20(D) |

| Weight(g) | 39 |

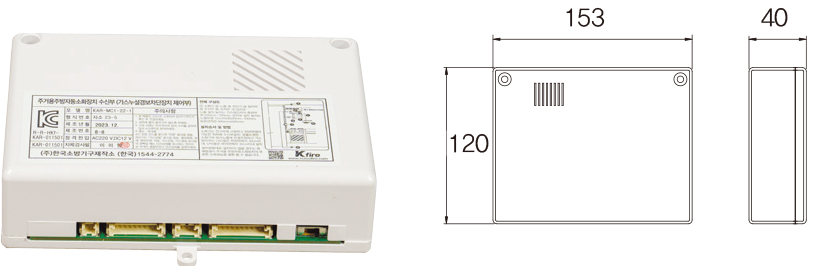

| Dimension(㎜) | 153(W) × 120(H) × 40(D) |

| Weight(kg) | 0.32 |

| Primary Sensing | Nominal Working Temperature : 95°C |

| Secondary Sensing | Nominal Working Temperature : 135°C |

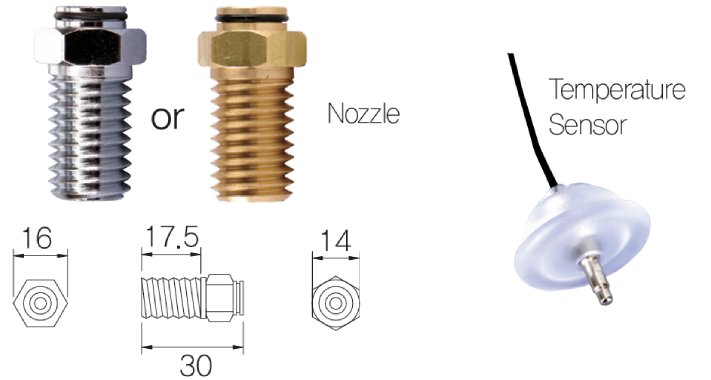

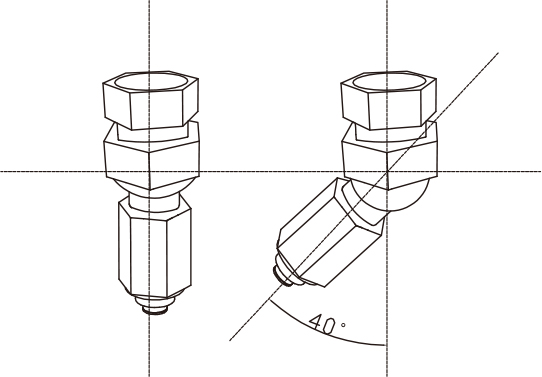

| Spray Nozzle | Discharging Time : 12seconds Discharging Angle : 80° Standard Type Protection Space : 695mm×695mm Effective Installation Height : 500~700mm Wide Type Protection Space : 850mm×850mm Effective Installation Height : 680~780mm |

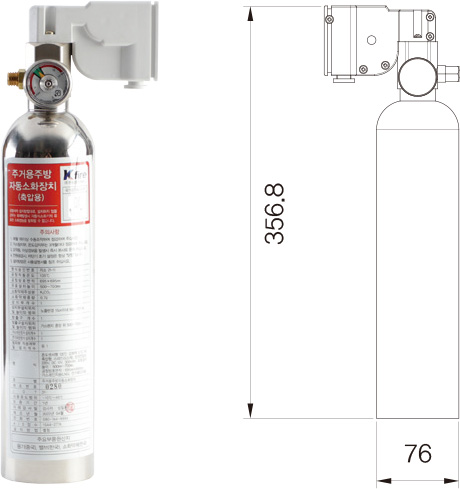

| Dimension(㎜) | 76 (W) × 356.8 (H) |

| Capacity(ℓ) | 0.8 |

| Weight(kg) | 1.88 |

| Main Ingredient | Potassium Acetate(CH3COOK) |

| Rated voltage | DC 12V |

| Applicable Gases | LNG |

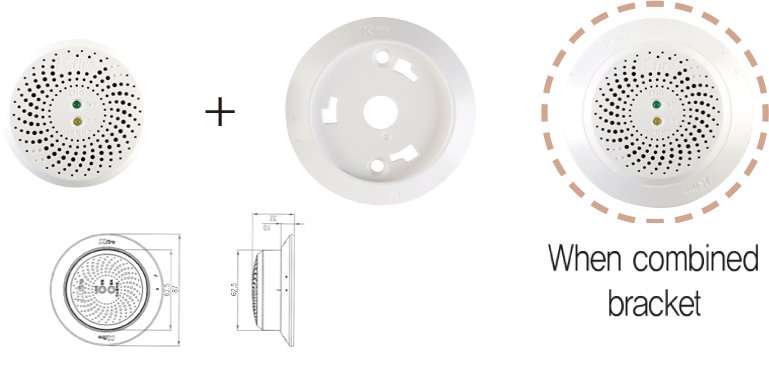

| Dimension(㎜) | 61 Ø × 32(D) |

| Weight(g) | 60 |

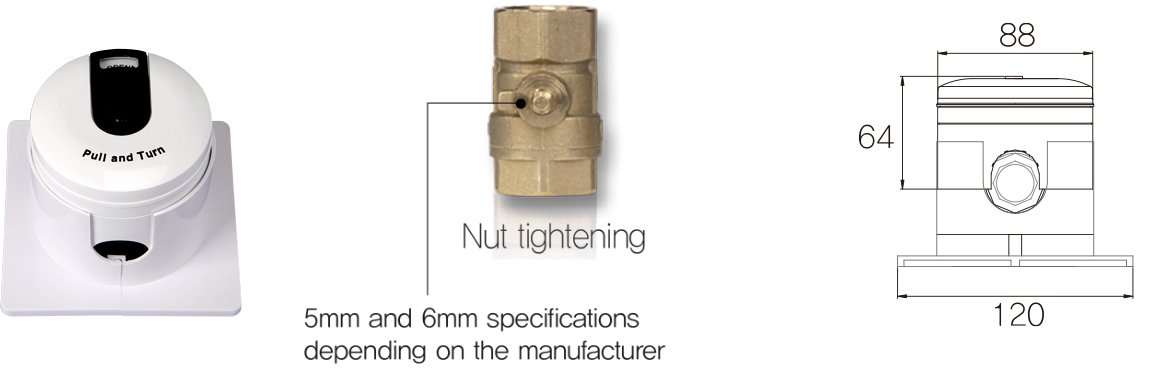

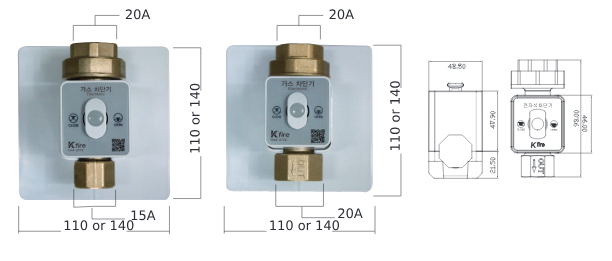

Mechanical Gas Circuit Breaker

Mechanical Gas Circuit Breaker

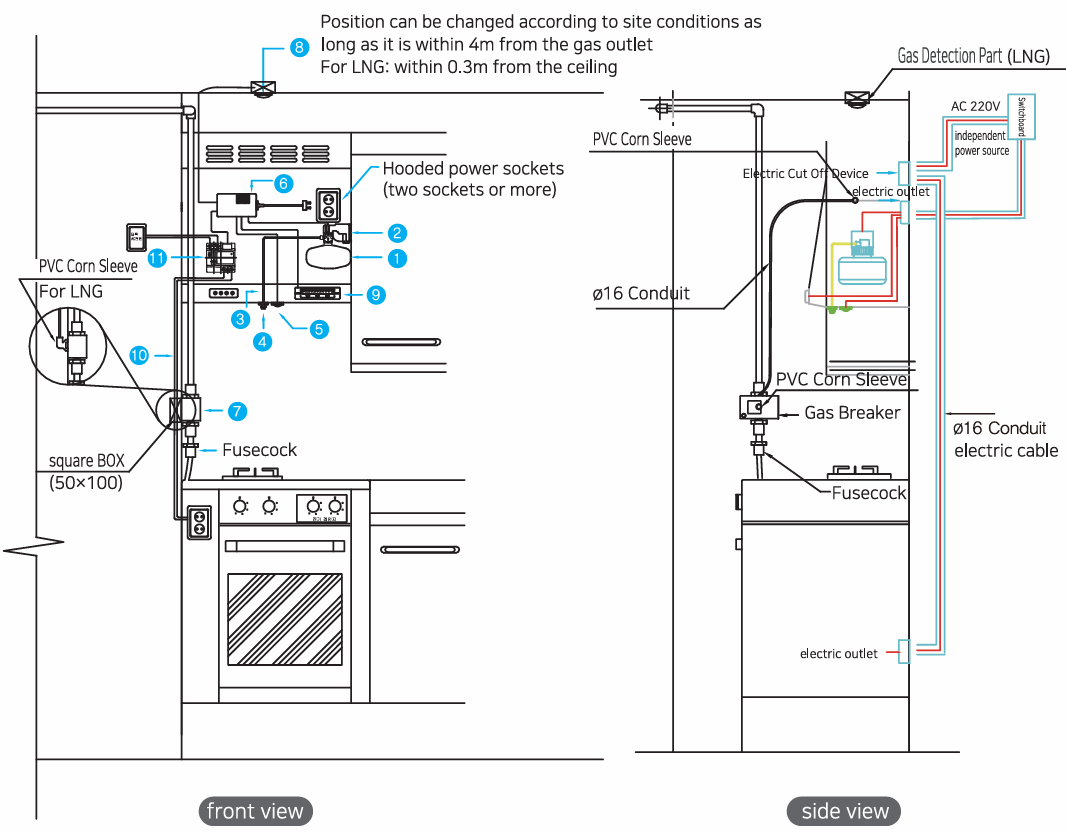

Gas Circuit Breaker Installation

Gas Circuit Breaker Installation

Gas Circuit Breaker

Gas Circuit Breaker

Gas Circuit Breaker Installation

Gas Circuit Breaker Installation

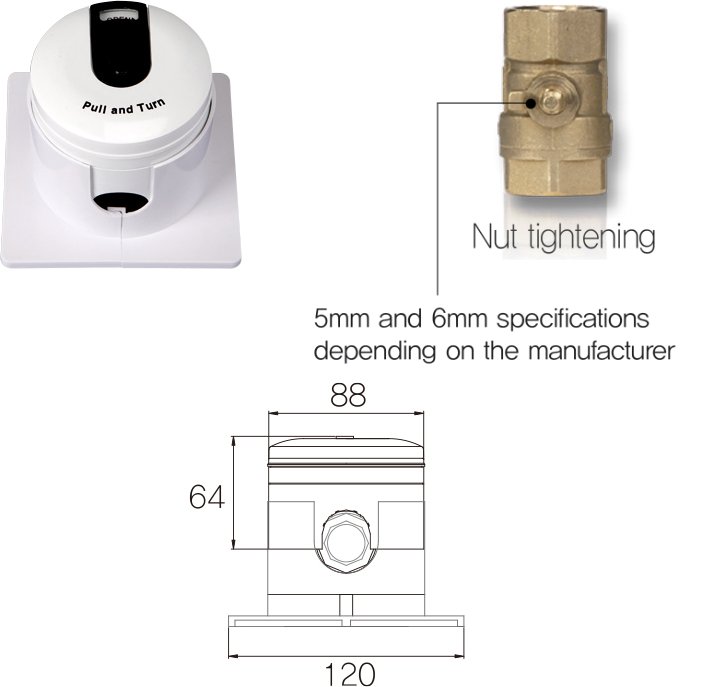

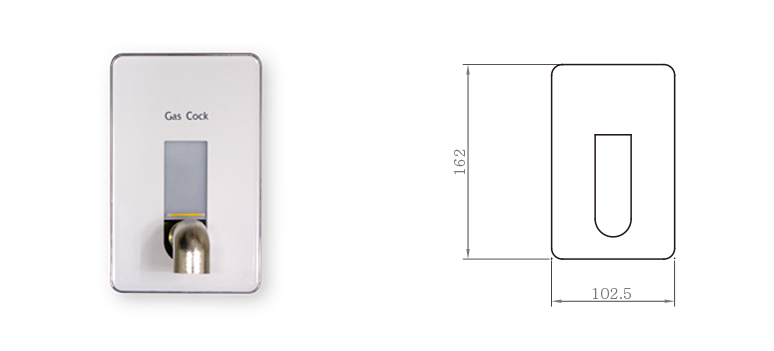

Embedded Gas Circuit Breaker

Embedded Gas Circuit Breaker

Gas Circuit Breaker Installation

Gas Circuit Breaker Installation

Integrated Gas Circuit Breaker

Integrated Gas Circuit Breaker

Gas Circuit Breaker Installation

Gas Circuit Breaker Installation

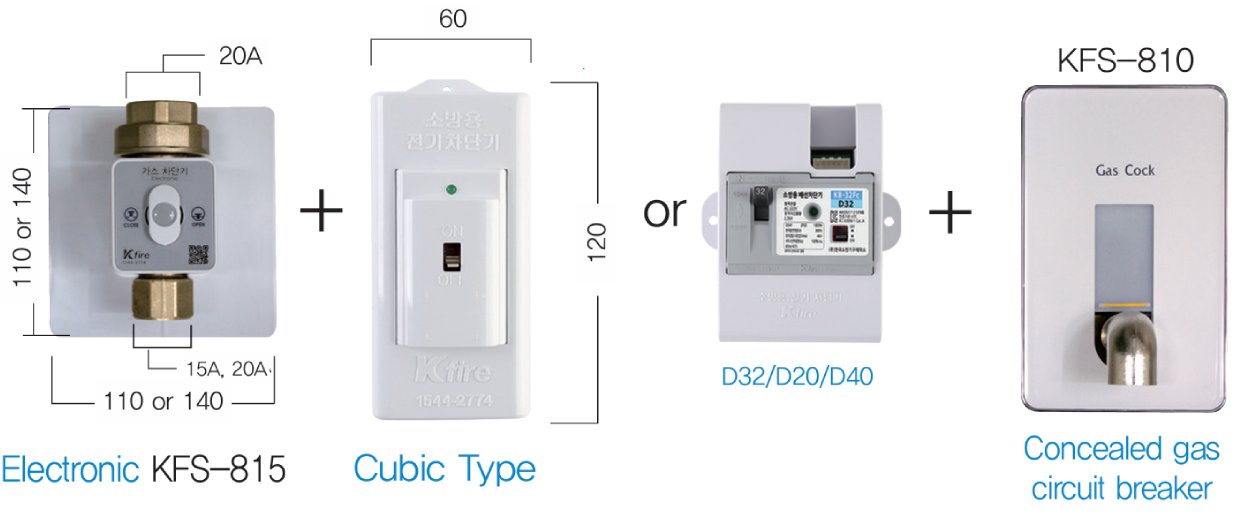

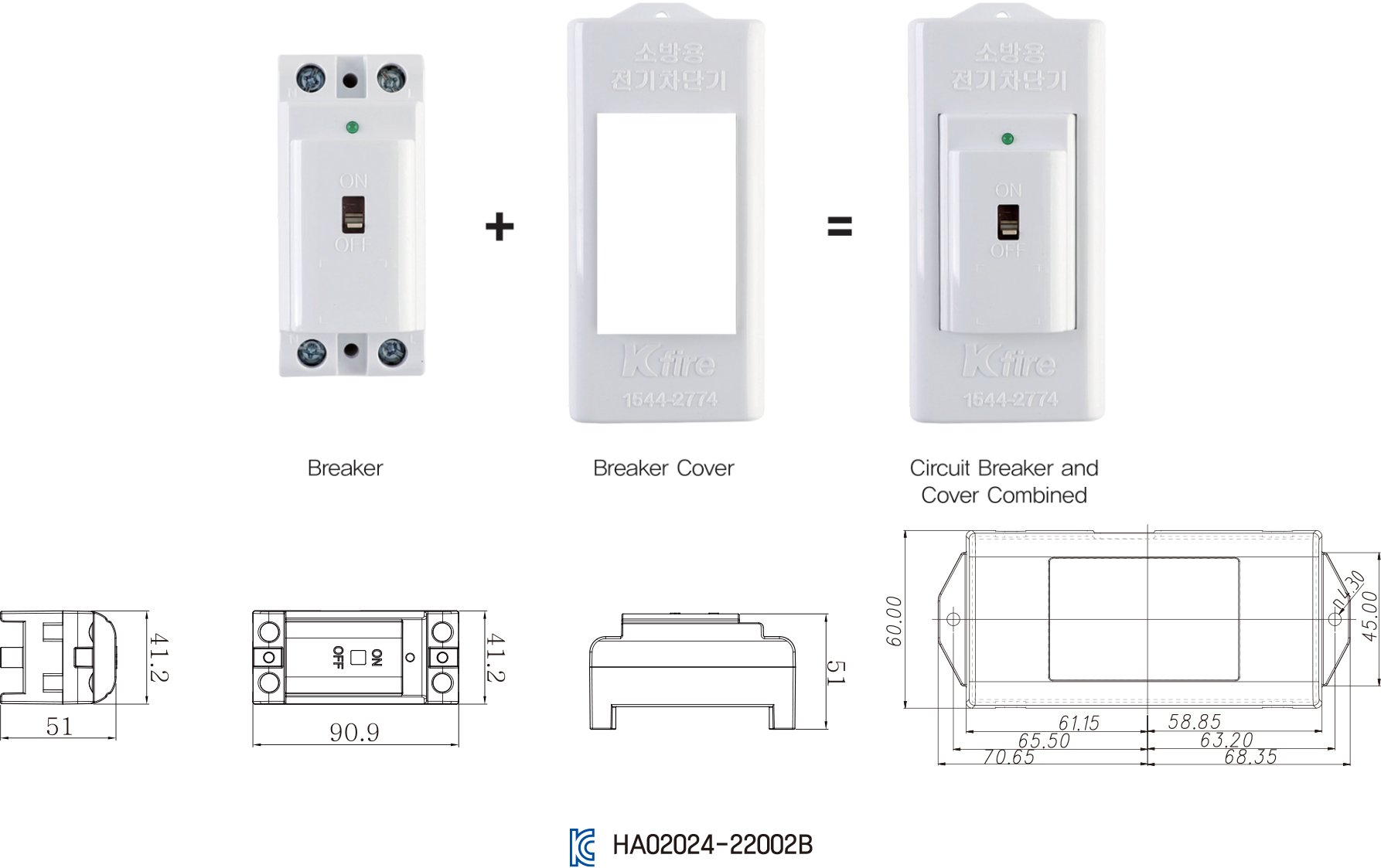

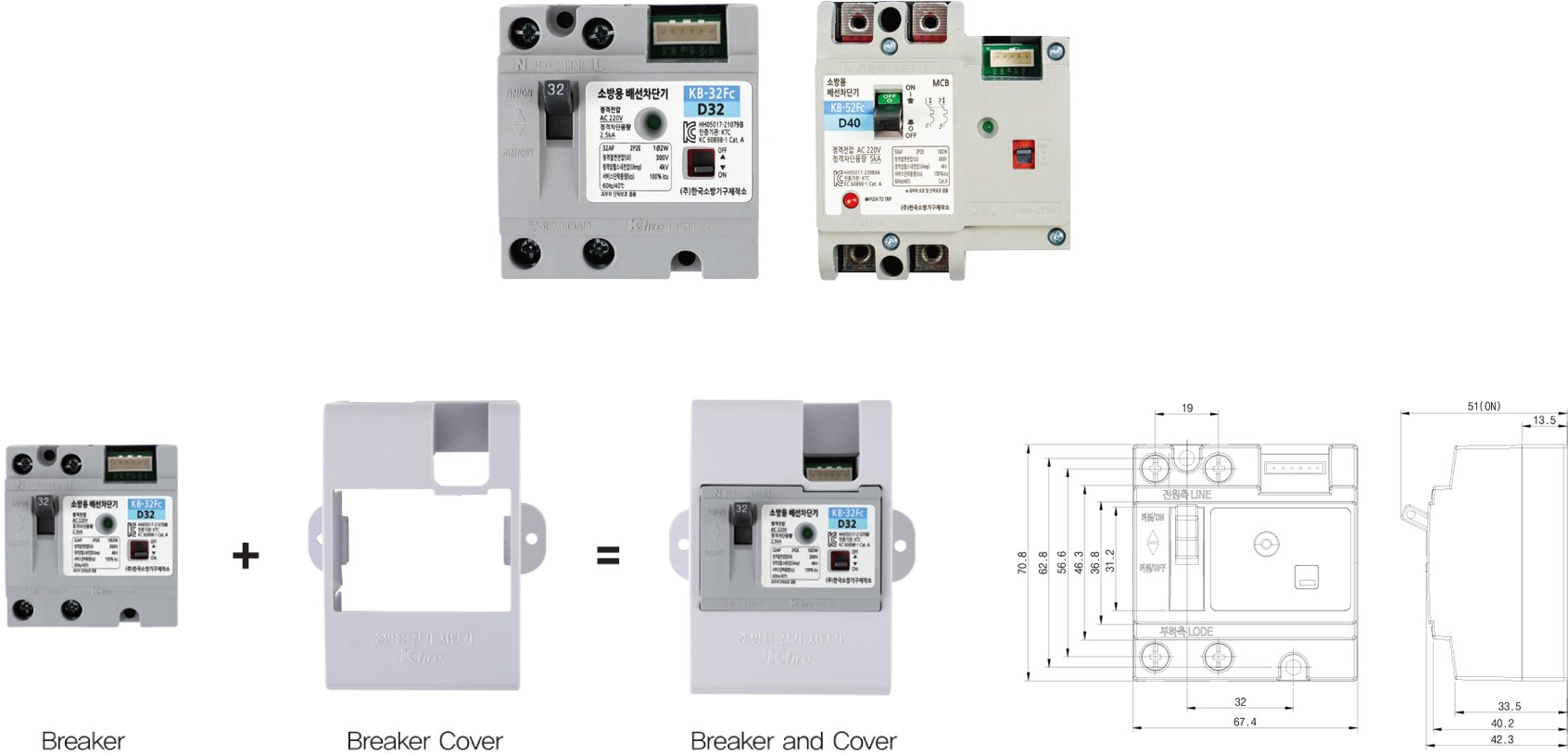

Electric Circuit Breaker

Electric Circuit Breaker

| Rated Voltage | AC220V / 60㎐ |

| Rated Current | 16A |

| Operative pressure | DC 12V |

| Name | Wiring circuit breaker (for housing) | |||

| Type Approval | HH05017-21079B | HH05017-21079B | HH05017-23089A | HH05017-23089A |

| Model | KB-35Fc D20 | KB-35Fc D32 | KB-40Pc D40 | KB-52Fc D40 |

| Rated Voltage | AC 220V | AC 220V | AC 220V | AC 220V |

| Rated Current | 20A | 32A | 40A | 50A |

| Phase | 2Phase | 2Phase | 2Phase | 2Phase |

| Weight | 160g | 160g | 160g | 160g |

| Display | Green LED switch on | Green LED switch on | Green LED switch on | Green LED switch on |

| Installation | Bracket or sole wall fixation | Bracket or sole wall fixation | Bracket or sole wall fixation | Bracket or sole wall fixation |

| PCB | 2Layer/FR4 | 2Layer/FR4 | 2Layer/FR4 | 2Layer/FR4 |

| Size | 67(W)X50(H)X70(D) | 67(W)X50(H)X70(D) | 67(W)X50(H)X70(D) | 67(W)X50(H)X70(D) |

| Breacket Size | 98(W)X50(H)X112(D) | 98(W)X50(H)X112(D) | 120.8(W)X75.17(H)X144.47(D) | 120.8(W)X75.17(H)X144.47(D) |

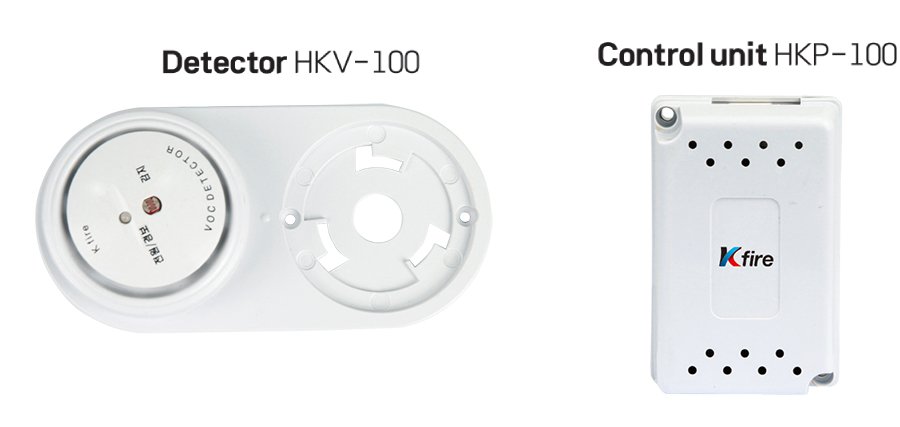

Detachable ventilation sensor HKVOC-100

Detachable ventilation sensor HKVOC-100

| Type | Detachable Ventilation Sensor |

|---|---|

| Model | HLVOC-100 |

| Power | AC 220V/60㎐ |

| Sensing gas | Alcohol, carbon monoxide, carbon dioxide, cigarette smoke, ammonia, various smells, etc |

| Power consumption | 1W |

| Usage temperature | -10 ~ 50℃ |

| Interlocking | Range Hood or Ventilation Fan |

| LED display | Blue LED-Power, Red LED-Relay operation |

| Installation | Kitchen in the house |

| Initial Stabilization Time | 3Minutes |

| Operating concentration | Approximately 20 ppm based on LNG |

Commercial Kitchen Automatic Fire Extinguishing System

Commercial Kitchen Automatic Fire Extinguishing System

Hybrid Method: A system that enables control of both electric ranges and gas cooktops

· The KISENⓇ system can be applied to five types of cooking equipment: fryer, griddle, range, wok, and gas broiler.

· The KISENⓇ system detects fire using a temperature sensor. If the temperature exceeds the set threshold, it sends a fire alarm. Then, the extinguishing agent stored in the extinguisher is discharged evenly to the protected area around the fire detection point, suppressing the fire and preventing it from spreading.

System Operation Process

System Operation Process

KISEN System Configuration

KISEN System Configuration

| Material | Stainless Steel |

| Size | 800×280×350(mm) |

| Extinguishing Agent Capacity | 1 bottle(12L) |

| Material | Stainless Steel |

| Size | 800×280×700(mm) |

| Extinguishing Agent Capacity | 2 bottle(24L) |

| Material | Stainless Steel |

| Size | Ø180×580mm |

| Capacity | 13L(Enhanced liquid agent 12L) |

| Pressurization Method | Nitrogen(N2) pressurization |

| Charging Pressure | 100kg/㎠ |

| Operating Pressure | 8kg/㎠ |

| Activation Method | Activated by detector or manual switch, pressurized with nitrogen |

| Main Extinguishing Agent | Enhanced liquid agent |

| Discharge Time | Approx. 30seconds |

| Operating Temperature Range | 0℃~50℃ |

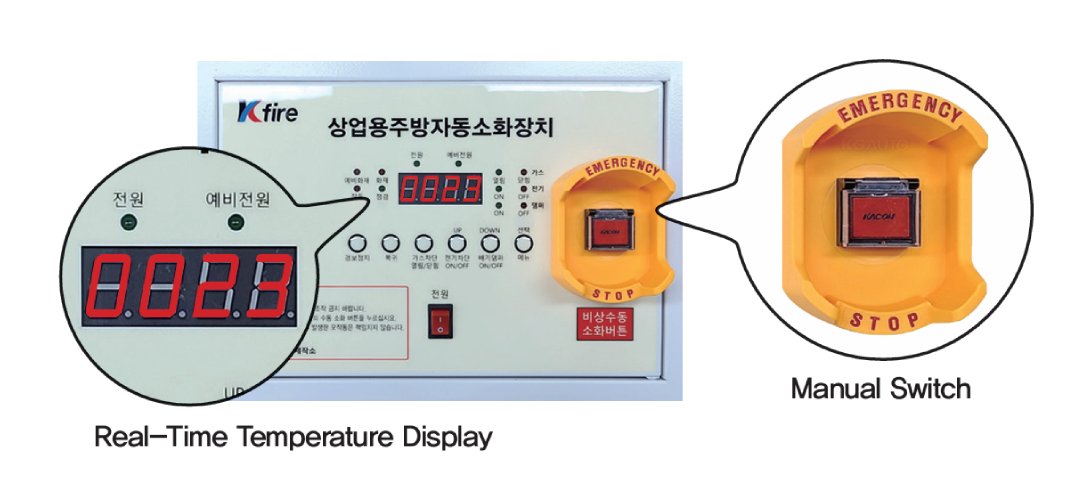

| Detection Method | Thermistor type |

| 1st Detection Temperature | 100℃ (adjustable) |

| 2nd Detection Temperature | 130℃ (adjustable) |

| Operating Range | 0 ~ 300℃ |

1st Fire Detection Temperature (preliminary fire temperature): This is the stage before an actual fire occurs. When the temperature detected by the sensor rises above the normal level and reaches the preset temperature (100°C), the system issues a warning.

2nd Fire Detection Temperature (actual fire temperature): When the temperature reaches the preset level (130°C), it indicates that an actual fire has occurred, such as ignition of combustibles (appearance of flames), or a situation where ignition is imminent due to high temperature.

| Setting Range | Up to 6 temperature sensors can be set |

| nstallation Capacity | Can use up to 2 extinguishing cylinders / Nozzle calculated for discharge amount (15kg) / 1 gas shut-off valve, 1 electric shut-off device used |

| Size | 300×210×75(mm) |

| Communication | 485 and contact available |

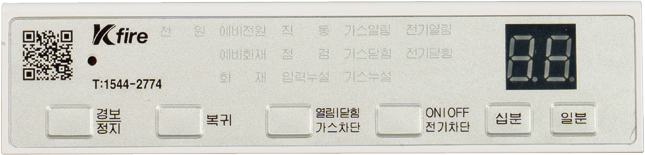

In the case of the receiver unit, the LED indicators, alarms, buzzers, and flashes intuitively inform the user of the current status of each protected zone via the FND display. Users can operate buttons to acknowledge or reset alarms and control the opening and closing of the gas shut-off valve.

| Nozzle No | KN01 | KN02 | KN03 | KN04 | KN05 |

| Applicable Equipment | Duct | Plenumt | Fryer | Range | Wok, Broiler, Griddle |

| Discharge Amount | 3.2kg | 1.8kg | 2.5kg | 3.1kg | 2.5kg |

| Material | Copper Alloy/Chrome Plating | ||||

Cooking equipment - This includes all equipment used in commercial kitchens that uses fuel, such as fryers, griddles, ranges, woks, and gas broilers.

Hood - Refers to the part of the exhaust system that collects smoke and steam generated during cooking and sends it out through the exhaust duct.

Duct - Refers to the sealed pipe connected to the exhaust equipment that allows smoke and steam generated during cooking to be vented outside.

Plenum - Refers to the space between the duct and the hood filter, or sometimes the inside of the hood without a filter.

Grease - While cooking, oils and fats can vaporize and adhere to surfaces as small particles in the air, accumulating on walls, ducts, and hoods. Since grease is one of the main causes of fire spread, facility users must remove accumulated grease regularly as a fire prevention measure.

A swivel adapter can be added to the nozzle, allowing adjustment up to a maximum angle of 40° as shown in the illustration, so the angle can be adjusted according to the position of the cooking equipment.

Enforcement Decree of the Act on Installation and Management of Firefighting Facilities

Enforcement Decree of the Act on Installation and Management of Firefighting Facilities

General restaurants located within large shopping malls as defined in Article 2, Subparagraph 3 of the Distribution Industry Development Act

Group catering facilities as defined in Article 2, Subparagraph 12 of the Food Sanitation Act

Distribution Industry Development Act

Distribution Industry Development Act

Stores that are installed within one or more interconnected buildings as defined by Presidential Decree, either as a single unit or divided into multiple units

Stores that are operated continuously

The total floor area of the stores is 3,000 square meters or more

Food Sanitation Act

Food Sanitation Act

Dormitory

School, kindergarten, daycare center

Hospital

Social welfare facility as defined in Article 2, Subparagraph 4 of the Social Welfare Services Act

Industrial establishment

National or local government and other public institutions as defined in Article 4, Paragraph 1 of the Act on the Management of Public Institutions

Other similar institutions

Enforcement Decree of the Food Sanitation Act

Enforcement Decree of the Food Sanitation Act

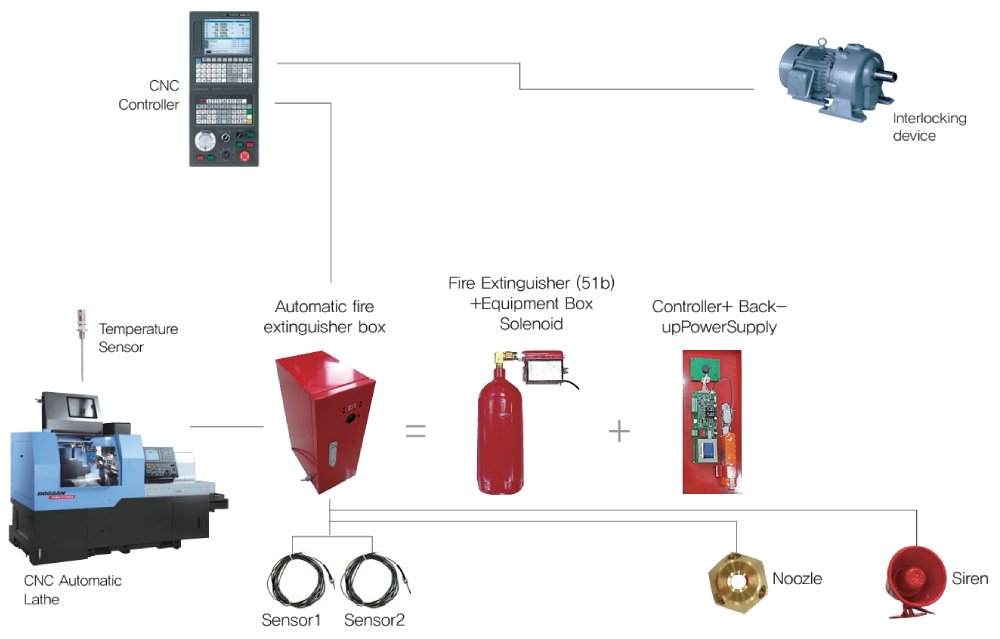

Product Overview

Product Overview

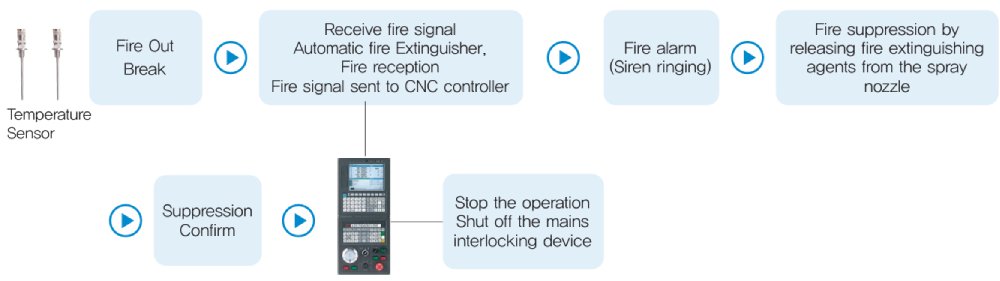

Install temperature sensors at the places of potential fire outbreak. If a sensor detects the temperature going up beyond theset temperature, it transmits a fire signal to automatic fire extinguishing equipment, and the automatic fire If the temperature is detected above the set temperature by installing a temperature sensor in the area where a fire is expected, the automatic fire extinguisher sends a fire signal to the CNC controller on the automatic shelf.

The CNC controller on the automatic shelf operates, interrupts, and shuts down the interlocking device, and sprays fire extinguishing agents from the spray nozzle to quickly extinguish the fire at an early stage.